Metrics can be a tough topic to convey to people who are used to deleting 50+ emails every day. It’s understandable that people will simply scan through an email without taking it in when the average employee spends 23% of their time reading mails (https://tinyurl.com/hmwadz7) or even just delete it outright when they receive many through the day.

In my job as Scrum Master two competencies I value include transparency and feedback. This applies the work I do as well as the teams I work with.

Metrics are important for a number of reasons including making us more predictable, identifying bottlenecks and primarily as an aid to help us improve. They are of use to a diverse range of people including Developers, Scrum Masters and Product Owners. So it is of some value if we can get interested parties to read and understand what the metrics are saying – the delivery of this information is important.

Several years ago I used to send the information out in the form of an email like this:

While this contained lots of information it proved to be an ineffective way to share it. I found that after months of delivering the data in this way people got bored and in the end didn’t read it. I sought out ways to improve the read count of this information and have managed to improve this. In searching for new ways to report I stuck to 3 simple rules:

- The information has to be presented in a simple way.

- The information has to be attractive to look at.

- The way we present the data has to change on a regular basis in order to keep peoples attention.

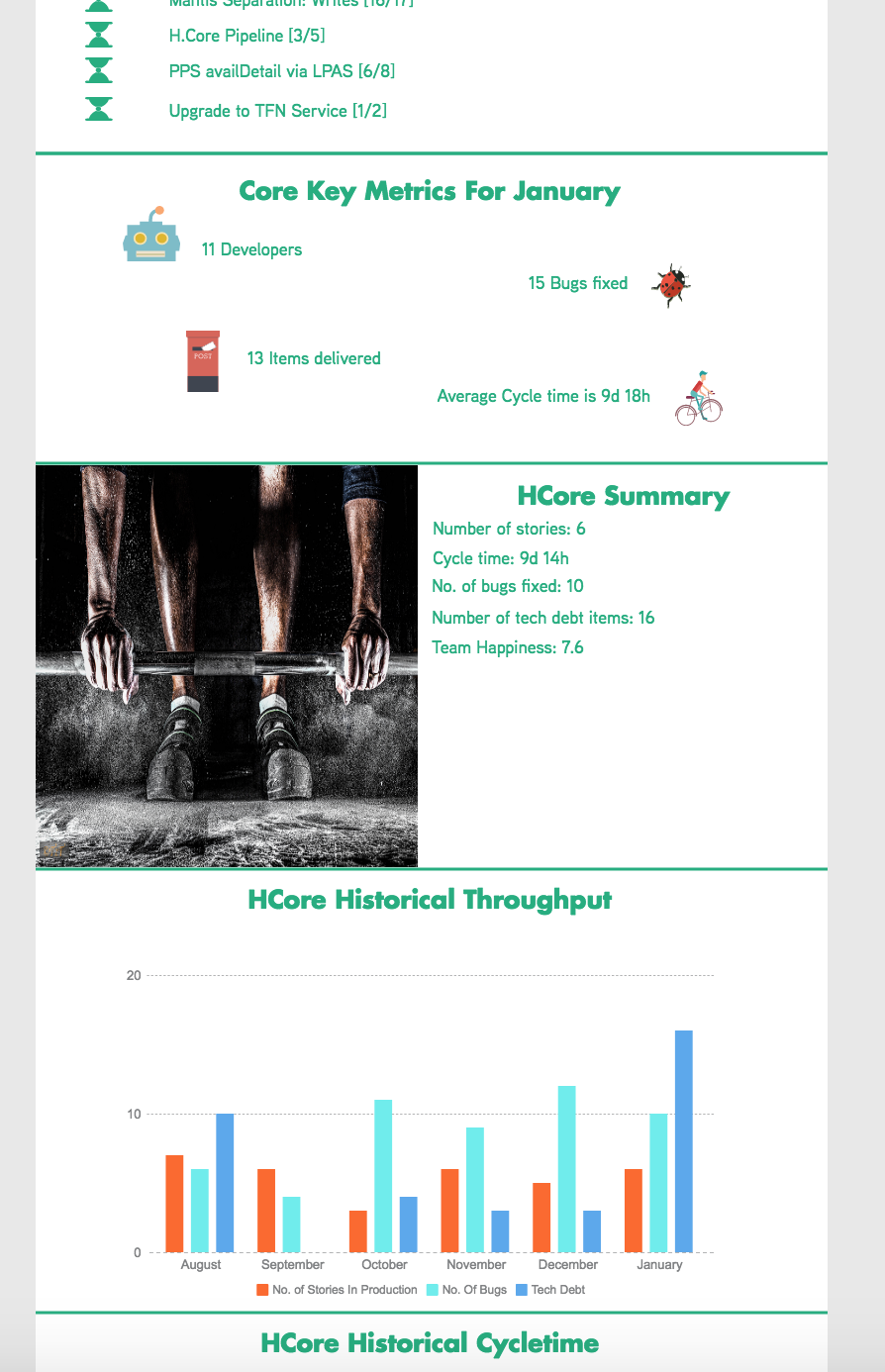

I discovered that there were web based infographic tools available which would solve most of these problems these include Venngage, Piktochart and Canva. Piktochart was the one I chose – mainly due to its easy of use.

This is what the report now looks like:

The full version can be found here.

This is simple, nice to read and I try to make sure that it looks different every time I send it out.

As well as improving the presentation and the delivery of the report, I also look to improve the metrics we collect every month. It is also good to focus the report on areas to tackle whichever problems the team are facing. All of these have helped to improve the transparency and feedback to the team and stakeholders.